One of the biggest challenges of the 21st century is the search for alternatives to petrochemical production of chemicals and fuels. One approach is the use of biomass, especially in the food industry. Several economic systems are already operating on an industrial scale for the production of bioethanol. The waste industry fruits and other agricultural residues are the main raw material. Butanol (long chain alcohol) may also be produced by biotechnological processes, which offers some advantages over ethanol: Increased energy storage per unit volume. This is of great interest to the aerospace industry, because it means a reduction in weight and hence a saving in fuel consumption. It also represents greater safety during storage, due to the lower volatility of butanol. The butanol is less corrosive, it can be transported in existing piping systems and no modification for use in conventional engines is required. One advantage is that butanol can be used as a pure fuel, unlike gasoline, representing a greater combustion efficiency, as shown in the following table:

| Energia [MJ/L] | Punto de ebullición [°C] | |

| Gasoline | 32 | 70 – 150 |

| Butanol | 29 | 117,4 |

| Ethanol | 19.6 | 78,37 |

Butanol has a wide range of applications in the chemical industry. butanol is required for the production of paints, surface coatings and adhesives.

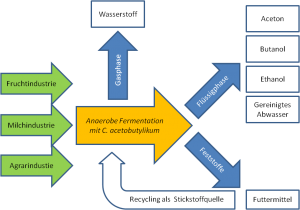

The fermentative production of acetone, butanol and ethanol, the process known as ABE (acetone, butanol, ethanol) flourished from 1930 to 1950, until it was supplanted by cheaper petrochemicals. During EBA, the natural ability of several species of Clostridium, is used to prepare the solvents mentioned under anaerobic conditions from a wide variety of mono- and disaccharides. You can use bioethanol yeasts and Clostridia; also they are used pentoses (5 C-sugar), which significantly increases the range of usable waste sources. In modern fixed bed reactors, the natural ability of clostridia is used to achieve higher flow rates without causing a washed biomass continuously operated reactor. This leads to a considerable increase in productivity and therefore the cost effectiveness of the process. In laboratory experiments with dairy effluent they are achieved Butanol productivities of 4.43 g / L h. The resulting fermentation gas is separated and the hydrogen is used as an energy source. Recyclable materials contained in the fermentation broth, such as acetone and butanol, are purified with adsorption innovative method that requires less than 10% of the energy content contained in recyclables. The solids are removed before adsorption of valuable materials and added to the process as a nitrogen source of new or used as animal feed.

Purification of wastewater from the food industry, and the high COD (chemical oxygen demand) value and solid parcialmentegrandes, are a significant part of total production costs (up to 500 € / m³). Therefore, converting this waste into valuable products such as butanol, offers the opportunity to reduce these costs or even make a profit from wastewater. The annual demand for butanol is 4-5 million tons with a range of $ 6-7 billion.

The annual increase in demand is estimated at around 3%. Recycling of waste materials is essential to meet growing demand and to conserve resources.

Deutsch

Deutsch English

English Español

Español